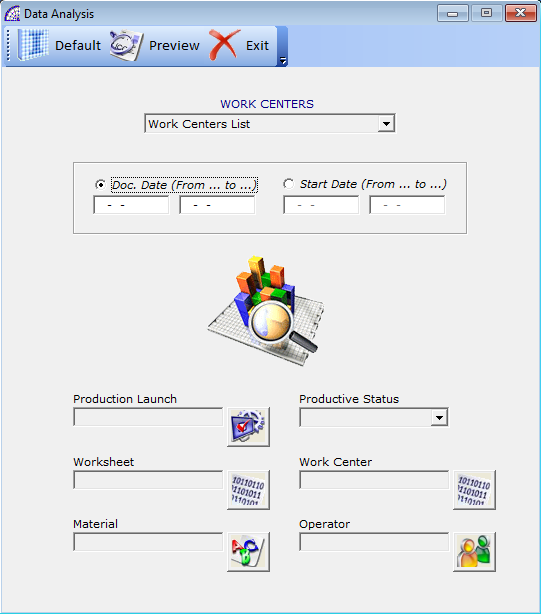

WORK CENTERS ANALYSIS

Extracts in an analytical form of the prints detailing the total time worked by the various work centers, in the loaded production launches.

Work Center List: synthetic report summarizing by work center the total worked per unit of measure.

Completed List of the Work Center: detailed report where, for each work center, the hours worked for production launch are displayed, also indicating the operator involved.

In the window there are various filters that limit the results of the reports: Doc. Date (From … to …), Start Date (From … to …), Production Launch, Productive Status, Worksheet, Work Center, Material, Operator.

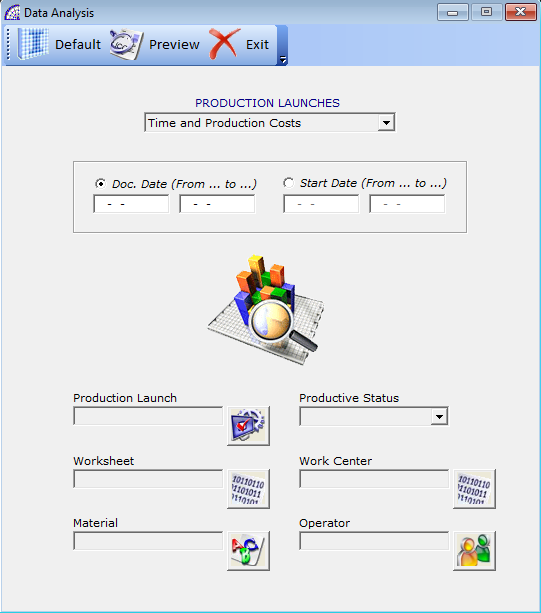

… PRODUCTION LAUNCHES

Extracts in an analytical form of the prints detailing the list of tasks, subdivided by BOM and/or job order, for each existing production launch.

In detail we find the different times and costs, for each one the estimated values, the final balances and the percentage variations are indicated.

Like the previous reports, the filters are available to limit the results.

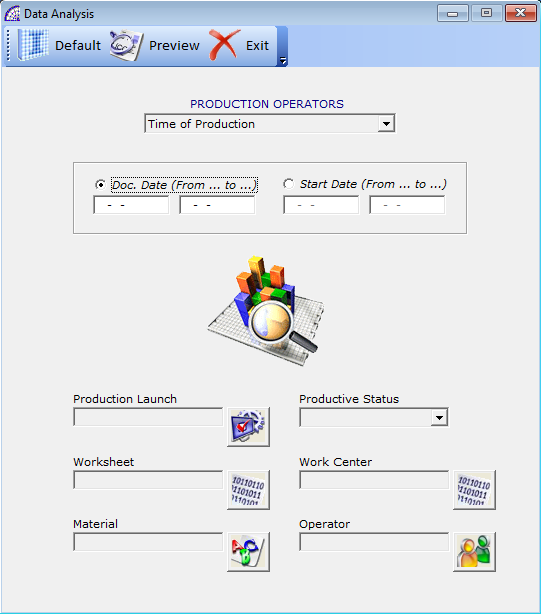

… OPERATORS

Extracts in an analytical form of the prints detailing the list of work done by the personnel of the departments.

Time of Production: displays a report with a summary of the total work done by operator, expressed in the chosen unit of measure (hours or minutes or seconds).

Time and Production Costs: displays for each operator the detail of the hours worked, for production launch, department, start and end date and time.

Operator Presence: displays a report by period, with the presence tracking movements created in the system. For each one the name of the operator is indicated, the date and time of entry and exit, and presence in terms of hours.

Quality Control: display a report with the quality tracking movements inserted in the detection time system. For each one the name of the operator is indicated, the production launch reference, the work center reference, date and time and result of the control.

Like the previous reports, the filters are available to limit the results.

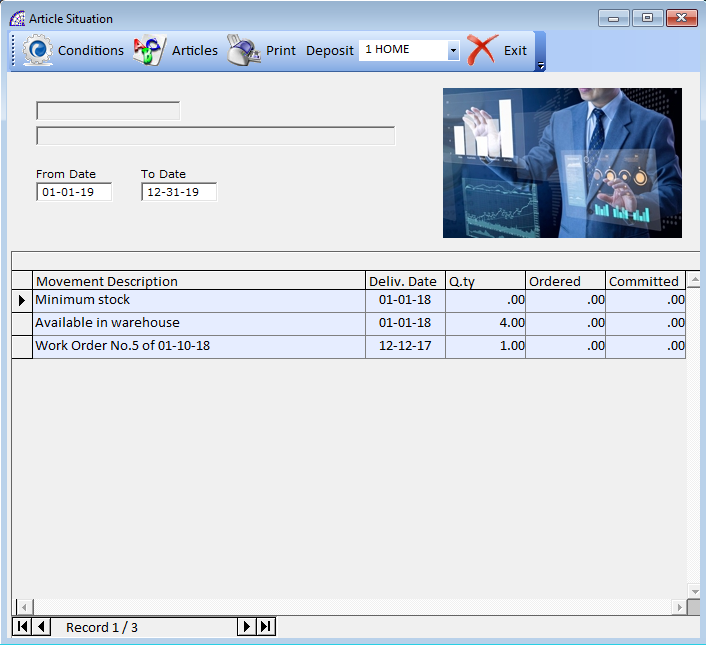

ARTICLE SITUATION

Provides a graphical query tool for each warehouse article, showing in descending order the list of movements undergone.

For each detail row (movement), a specific description is displayed indicating the nature of the movement, a delivery date, and the three movement fields present in the warehouse (Q.ty, Ordered, Committed).

The first movement created (due to the descending order by date, appears at the end of the list), is “Available in warehouse”: indicates the value present at the beginning of the year (in the “Q.ty” column), in the warehouse selected in the toolbar of this window.

Conditions: performs the calculation to display the movements of the selected warehouse article, within the time period indicated by the date fields.

Articles: allows you to select the reference item (mandatory field).

allows to select the reference warehouse.

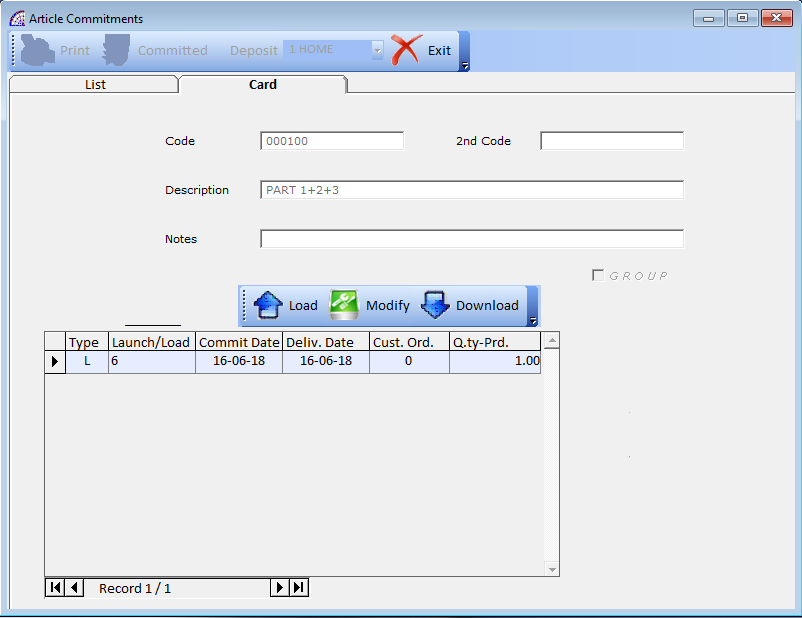

ARTICLE COMMITMENTS

A detailed view of the production commitments of the warehouse items, automatically generated by production launches and production loads movements, before the evasion planned for these particular industrial processes.

A detailed view, however, present in the warehouse management window (from the main menu select “@/Arpro” + “Warehouse Articles”), which optimizes the consultations or any necessary adjustments.

if active, displays only warehouse items that have a production commitment, highlighted by a value from the “Prod. Q.ty” column.

allows to select the reference warehouse.

Once an article has been selected, it is possible in the “Cardv tab to visualize in detail the data related to production commitments.

For each commitment line, in the “Type” column the program indicates whether it was generated by a production launch (L) or a production load (C). The references of the production movement, the dates of creation and delivery, the possible reference to the sales order, the quantity committed are also shown.

The toolbar linked to the movement grid has controls to possibly rectify this data: upload new entries, correct existing ones, delete.

In the “List” tab, as well as in the management of the article warehouse, it is therefore possible to view the articles that present an inventory available. This value is given by the following mathematical operation: Q.ty – Committed – Prod. Q.ty.

Q.ty -> quantity of articles available (at the moment)

Committed -> quantity committed by customer orders

Prod. Q.ty -> quantity committed by launches or production loads

MICROSOFT PROJECT®

Microsoft Project is a planning software developed and sold by Microsoft. It is a tool to assist project managers in planning, allocating resources, checking time compliance, managing budgets and analyzing workloads.

The @/Arpro Erp program has a “channel” of connection with Microsoft Project® to extract, in real time, production data.

It is possible to view the production situation in the host platform, using Gantt® charts, in relation to the pending production launches, where the various planned and/or completed tasks are displayed setting them in the time frame (X axis of the graphs) provided.

We have implemented procedures to be installed on the Microsoft Project® platform to facilitate data import, keeping them updated to the current production situation, as well as specific procedures to write in the @/Arpro Erp production launches the modified data resulting from the assessments carried out in the Gantts.

The possibilities of integration in this area are different, among other things, the procedures described above are provided in source format to allow companies with development capacity to adapt them to specific needs.

Our company is still available to evaluate customization requests, in response to specific needs. Please contact our technical departments or send a request by mail to sales@arpro-solutions.com.

VARIOUS PRINTS

In all cases where customized printouts are required, which are not available among those available, @/Arpro Erp provides a tool to connect external printouts and transfer all of the parameters necessary for their execution.

However, the creation of external printouts requires good knowledge of the Object Crystal Report(R) tool, necessary for the creation of the same. In these cases we advise you to contact qualified personnel.

CALCULATOR

It is possible to keep this window open in the program in case it is necessary to perform calculations, perhaps on board the machine in production, without having any calculator.

OTHER

It is possible to customize 3 menu items in the main menu, to be able to insert the references to open external programs.

To do this you need to enter the program configuration, customize the “Integrative Procedures” section.

“Menu Item”: these are the items that will appear in the “Analysis” + “Other” main menu.

“Procedure Path”: indicate the paths of the various external programs.